TEL

CONTACT

Address

Room 703,No.28 Huahai Road.Economic and technical development zone,Shenyang P.R.China

ZIP:110143

+86-024-25558500

WE ARE COMMITTED TO PROVIDING CUSTOMERS WITH

HIGH QUALITY PRODUCTS,COMPETITIVE PRICES AND EXCELLENT SERVICES

All rights reserved Shenyang Bona Titanium Technology Co.,Ltd. 辽icp备17016579号Powered by300.cn shenyang.300.cn

Titanium Plate Specialty

Titanium plate implementation standards are two, the national standard is GB / T3621-2007, GB / T13810-2007, American standard is ASTM B265, ASTM F136, ASTM F67, AMS4928.

Titanium plate manufacturing process

A forging process carried out at a metal recrystallization temperature.

Hot rolling is carried out at a temperature higher than the recrystallization temperature.

Cold rolling plastic deformation temperature is lower than the recovery temperature of the rolling process.

An organic heat treatment process in which the metal is slowly heated to a certain temperature, maintained for a sufficient time, and then cooled at a suitable rate (usually slow cooling, sometimes controlled cooling).

Pickling: The part is immersed in an aqueous solution of sulfuric acid or the like to remove a thin film such as an oxide on the metal surface. Is electroplating, enamel, rolling and other pre-treatment or intermediate processing

Titanium plate characteristics

1. Titanium plate is the surface of the oxide film is equivalent to a good wear and tear with the release agent, the use of titanium plate to save the separation agent, so that easy to peel off the plate, eliminating the pre-treatment process of the species, titanium The board is lighter than the copper plate.

2. Titanium plate life is more than 3 times the copper plate, according to operating conditions up to 10 to 20 years

3. With titanium plate made of electrolytic copper crystal structure dense, smooth surface, excellent quality.

4. Since the titanium plate without the need to apply the separation agent, which can avoid the pollution of copper electrolyte.

5. To improve production capacity to reduce the cost of electrolytic copper production, which has a better economic benefits.

What are the uses of titanium plates?

Titanium alloy with high strength, low density, good mechanical properties, corrosion resistance, high stability and other effects, but the more stable the metal, the more difficult to process them, so the process of production of titanium alloy is more complex and costly, so the Early use of titanium alloy is mainly used in aircraft engine parts, as well as rockets, missile flight components, etc., in addition to titanium alloy is the main application areas of military, scientific research, made into high strength, corrosion-resistant parts, It is very little.

With the continuous development of science and technology, titanium alloy to the present, the cost reduced a lot, has been applied to industrial, construction, and civilian, titanium alloy quality performance, leading to titanium products have been popular

Titanium in many media than stainless steel, aluminum and other stronger corrosion resistance. And the proportion of titanium light, higher than the strength. Titanium in the air and oxidizing, neutral aqueous medium, the surface is very easy to produce dense titanium oxide passivation film, the titanium electrode potential is significantly shifted, greatly improving the thermodynamic stability. The chemical stability was improved by 0.18, 0.34 for nickel, 0.49 for chromium, 0.74 for aluminum, 0.82 for aluminum and 2.44 for titanium.

(1) Titanium has a high hardness, light weight, anti-corrosion characteristics, due to the superior properties and characteristics of titanium, they are made into titanium equipment is widely used in industrial, chemical and many other fields.

(2) titanium and titanium containers generally do not require assessment of impact toughness.

(3) titanium has excellent corrosion resistance, of which industrial titanium TA1, TA2, more than 90% for the civilian industry to produce a variety of titanium equipment, and these titanium equipment for the production of titanium into a container, So our titanium containers in the titanium industry occupies a pivotal position.

(4) titanium does not exist as ferrite steel as low temperature brittleness problem, titanium can be used as low temperature -269 degrees of low temperature containers, but because of austenitic stainless steel, aluminum, copper, etc. can also be used as low temperature containers, And titanium is cheaper, so titanium is rarely used for low-temperature fixed containers, in the air, aerospace titanium used as mobile low-temperature containers, the use of titanium is the use of high specific strength, light weight characteristics.

(5) In seawater, salt water and other chlorine-containing medium, carbon steel, low alloy steel, general stainless steel, aluminum corrosion resistance are not good, and titanium has a unique excellent corrosion resistance, about 50% of the titanium container In the anti-chlorine-containing media corrosion.

(6) Since the corrosion resistance of titanium is due to the surface oxide film, so the general industrial titanium and titanium alloy in high temperature hydrochloric acid and other strong reducing medium is not corrosion. Ti-32Mo can be resistant to hydrochloric acid corrosion, but its plasticity and process performance is poor, not yet included in the pressure processing of titanium standards, is not included in this standard as a container with titanium.

(7) titanium in certain conditions of fuming nitric acid, dry chlorine, methanol, trichlorethylene, liquid nitrous oxide, molten metal salts, carbon tetrachloride and other media may produce combustion, explosion or stress corrosion, so that titanium containers Produce a malignant accident, titanium containers on these media should be avoided or caution.

(8) Titanium will burn at temperatures in excess of 500 ° C or more than 1200 ° C. Titanium containers may not be exposed to open flames in contact with air and oxygen to avoid burning of titanium containers.

Product Description

High Quality Hot Selling Aluminium

Specifications

1. Aluminum ingot 99.97

2. Grade: Pure aluminium

3. SGS/CIQ/BV...Any inspection u need

4. ISO9001: 2000

Chemical Composition: Al

Weight: 20/25kg

Al (Min): 99%-99.9%

Place of Origin: China (Mainland)

Appearance: Silvery white

Aluminum ingot for remelting is produced by molten salt electrolysis method using alumina and cryolite. Products meet the national standard GB/T1196-2002. The surface of ingot is clean and smooth.

Specifications

Brands: Al99.85, Al99.80, Al99.70

1, Aluminum ingot manufacture.

2, high standard.

3, High quality.

4, Competitive price

Brands: Al99.85, Al99.80

Chemical Composition: Al

Weight: 20/25kg

Al (Min): 99%-99.9%

Place of Origin: China (Mainland)

Appearance: Silvery white

Aluminum ingot for remelting is produced by molten salt electrolysis method using alumina and cryolite. Products meet the national standard GB/T1196-2002. The surface of ingot is clean and smooth.

|

Item |

Aluminum Ingot |

|

Grade |

1060,1100,1200,2024,2124,2014,2124,3003,3004,3006,3030,5052,5083,5154,5454,5754,5005,5652,6061,6062,6063,7075,etc |

|

Standard |

GB/T3191-1998,ASTM B221M-05A,JIS H4040-2006,etc |

|

Diameter |

2-800mm |

|

Length |

2m,3m,5.8m,6m,or as required |

|

Finish Condition |

O,H14,H12,H16,H18,H22,H112,T5,T6,T651,T351,T42,T451,T62,T3,T81,etc |

|

Surface |

Mill finish,polished,anodizing,brushing,sand blasting,powder coating,etc |

|

Price term |

Ex-Work,FOB,CNF,CFR,CIF,FCA,DDP,DDU,etc |

|

Payment term |

TT |

|

MOQ |

20MT |

|

Package |

Standard export package, or as required |

|

Export to |

Iran,India,Indonesia,South Africa,South Korea,Saudi Arabia,Kuwait,Korea,Canada,USA,Thailand,England,Australia,Nigeria,Italy,Peru, Mexico,Malaysia,Myanmar,Chile,Saudi Arabia,Chile,Suriname,etc |

|

Application |

Aluminum ingot are widely use as Aircraft structure, rivets, missile components,truckwheel, screw elements, and other various structures |

|

Contact |

If you have any question,please feel free to contact me We are sure your inqury or requirements will get prompt attention. |

Applications:

1. Mainly used for melting ingot

2. Discontinuous melting with scrap

3. Easy control and operation

4. Fast melting

5. Used for industry such as automobile, pinning and weaving, electron broadly and so on.

Packaging & Delivery

Packaging Details

Standard export package ,or as required

Delivery Time

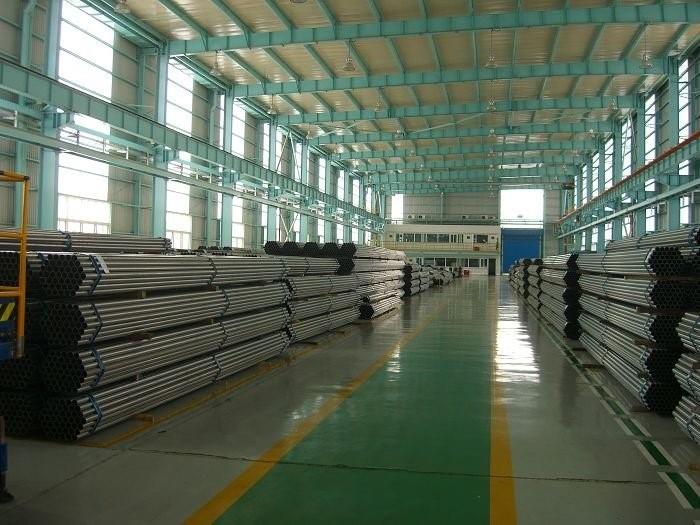

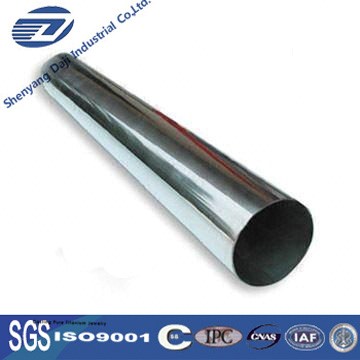

High quality seamless stainless steel pipe made in china

Specifications

seamless duplex stainless steel pipe

1)Grade:300,600,800series

2)O.D:0.33-300mm; W.T:0.08-6mm

3)Standard:ASTM AISI EN DIN GB.

High quality seamless stainless steel pipe made in china

Our Strength

Since 1993, nearly 20 years of experiment and experience, we explored and summarized the way to control the optimum temperature at the process of manufacture, which guarantee our products are good-looking, smooth both inside and outside; decelerate the aging problem, and the roughness is controlled not more than 5um.

Technical information

|

Grade |

TP 202,TP 304, TP 304L, TP 310/S, TP 316/316L,etc |

|

O.D |

0.33 –219 mm |

|

W.T |

0.08 –6.0 mm |

|

Length |

As for your requirement |

|

Standard |

ASTM, GB, AISI, JIS, DIN, etc |

|

Delivery Time |

10~50 days ,according to customer’s quantity |

|

Delivery Condition |

Pickled, polished, bright annealed, electrolytic polished |

|

Package |

Plastic bag for each piece then packed in seaworthy woven bags. |

|

Payment |

100% irrevocable L/C at sight, or T/T 30% deposit |

TITANIUM BENEFITS

§High strength,

§High resistance to pitting, crevice corrosion resistance,

§High resistance to stress corrosion cracking, corrosion fatigue and erosion,

§Cold bending for complex piping bends without fittings or flanges,

§High strength to weight ratio,

§Weight saving possibilities,

§Low modulus, high fracture toughness and fatigue resistance,

§Suitability for coiling and laying on seabed,

§Ability to withstand hot/dry and cold/wet acid gas loading,

§Excellent resistance to corrosive and erosive action of high-temperature acid steam and brine,

§Good workability and weldability.

Applications

1, Scientific research

2, Petroleum,

3, Chemical industry

4, Spinning and weaving

5, Instrument and apparatus.